Casting

mould is made to form the shape of the desired part and molten metal is poured in to fill the cavity, and then left to solidify

- Customised Chemistry Composition

- Specialized Finish Machining

- Non-Destructive Testing

- Stainless Steel Grade (304, 316/316L, 410 etc)

- Alloy Steel (4140 etc)

- Carbon Steel (Various Casting Grade Steel)

Cement Plant Hammer

Recycling Plant Hammer

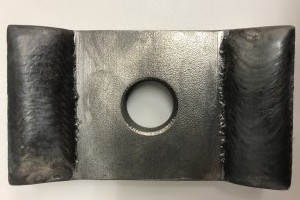

A pattern which is the actual configuration of the product is used to shape the sand/resin, which act as the mould to receive the molten metal to form the product upon solidification.

- Smaller batches

- Reasonable cost

- Bigger and heavier parts

- Allows most metals to be cast

- Valve Body

- Wear Resistance Plates

- Hammers

- Wheels

Casing Spool Head

Mining Wheel

An industrial process based on and also known as lost-wax precision casting. A technique for making small, accurate castings in refractory alloys using a mould formed around a pattern of wax which is then removed by melting. Molten metal is then poured into the cavity of the mould to form the product. Upon solidification, the mould shell is broken to reveal the finished part

- Can incorporate intricate contours

- Better accuracy

- Repeatability

- Versatility and integrity

- Good surface finish

Slip Carrier

Tactile Stud